Lindberg, the Danish premium eyewear brand, recently launched Thintanium – an all-new eyewear concept which is “most likely the thinnest full-plate titanium eyewear collection in the world,” according to the brand.

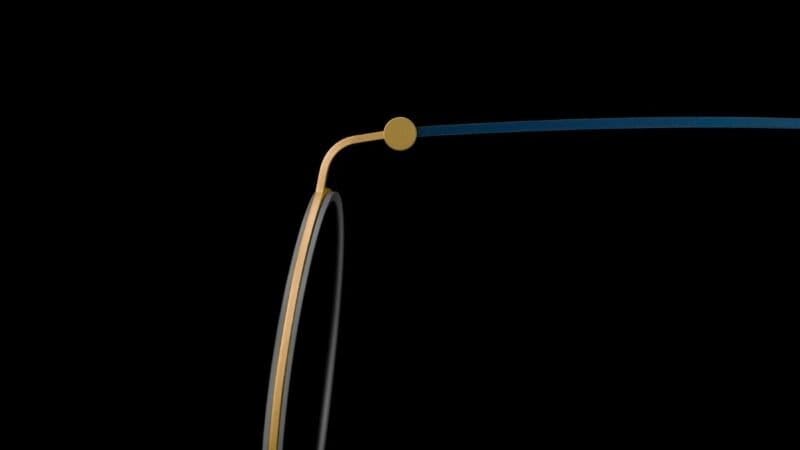

The collection gets its name from the patent-pending thin titanium strips developed by Lindberg’s engineers. The eyewear constructed using the hypoallergenic Thintanium looks essentially rimless in appearance, while still maintaining the stability of a full titanium front. The designs in this collection can weigh “as little as 3.0 grams.”

The collection also debuted a brand new, fully integrated screwless hinge, a prominent visual element to the design. The collection carries the added benefits of the Lindberg building system, which means everything can be tailormade to one’s preference and comfort, and this includes a selection of tinted lenses.

Lindberg is a family-run business co-founded by architect Henrik Lindberg and his optometrist father Poul-Jørn Lindberg more than three decades ago. An embodiment of Danish design, every Lindberg eyewear is ultra-lightweight and constructed with a minimalist approach – without screws, rivets or welded parts.

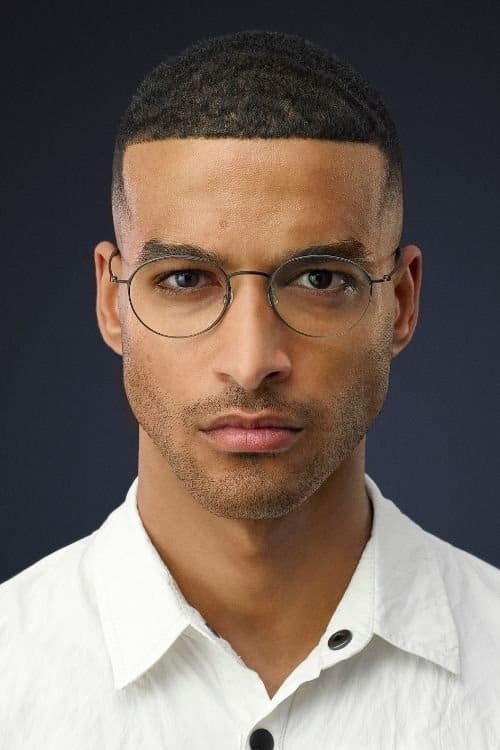

Signe spoke to Nikolaj Schnoor, Lindberg’s Global Chief Commercial Officer, who has been with the brand since 1997, to get a better understanding of the brand and its latest titanium innovation.

@page { margin: 2cm } p { margin-bottom: 0.1cm; direction: ltr; color: #000000; line-height: 120%; orphans: 2; widows: 2 } p.western { font-family: “Calibri”, sans-serif; font-size: 10pt; so-language: en-IN } p.cjk { font-family: “SimSun”; font-size: 10pt; so-language: zh-CN } p.ctl { font-family: “Candara”, sans-serif; font-size: 12pt; so-language: hi-IN } a.western:link { so-language: zxx } a.ctl:link { so-language: zxx }

Nikolaj Schnoor, Lindberg’s Global Chief Commercial Officer,

Why has titanium remained the metal of choice for Lindberg?

At Lindberg, we pride ourselves on using titanium. It is one of the most ingenious natural elements, high in quality and possesses unique properties – it is ultra-lightweight, flexible, durable, hypoallergenic and non-corrosive. Because of our experience and special treatment of titanium, we can bend and work with the material within very minimal tolerances. Our use of titanium is rooted in the Scandinavian design tradition that we belong to, where a substance to good design is choosing the right material.

Another useful feature the element holds is the way it can naturally change colour. Lindberg has a highly specialised and manual method that can result in slight colour variations of the rainbow. Currently, we have 36 different titanium colours where the wearer can choose their colour options for each part of their frame as part of the Lindberg customisation process.

What are the challenges involved in the design and manufacture of the new Thintanium collection?

This product is a success because of the collaboration between our in-house designers, engineers, toolmakers, production and commercial departments. For the Lindberg Thintanium, we have developed patented techniques and advanced technologies to craft the eyewear that meets the highest quality standards using our customised tools and equipment. New technology means that the right tools have only been available for a few years when our designers and engineers started developing the Thintanium concept.

In addition to our high-tech machinery, we depend on a team of skilled internal craftsmen to make our frames. Every pair of Lindberg glasses is individually assembled and hand-finished in our finishing lab – this includes a five-step polishing process followed by two rounds of hand polishing. We believe that premium eyewear, by definition, should always pass through human hands and never be mass-produced.

For the Lindberg Thintanium, the biggest complexity was the brand new hinge system, which was successfully developed based on our experience of working with titanium and investing in new technology.

What are the different aspects of customisation possible on the Thintanium collection?

Thintanium carries all the benefits of the Lindberg building system, which means everything can be customised to your preference and comfort. The customisable elements are many and varied, with your own choice of colour, size, temple length, nose pads and more. You can choose different groove colours to highlight the lenses or even opt for tinted lenses for a stylish look. So consumers can have fun exploring the possibilities and create their one-of-kind Thintanium eyewear.

Take us through the process of customising with the Lindberg building system?

The first step the customer should take is to visit an authorised Lindberg dealer. Our specialist opticians will guide every Lindberg customer through the collection and help them choose the perfect model, size, colour and material combination. Customers will also be fitted for the correct temple length and select the most suitable nose pad shape and size. In addition, every pair of Lindberg glasses is embossed with a unique identity number, and the wearer’s name can even be engraved on the inner side of the temple for the ultimate personal touch.

We see the need for customisation as the building system allows the wearer to have the ultimate fit and a one-of-a-kind look. This supreme building system had never been seen before, and it still has not in the world of mass-market. With this building system, we can tailor-make our eyewear down to the smallest detail. These details are what matters to the wearer; to have everyday comfortability and style.

How have the industry observers and aficionados reacted to the Thintanium collection?

The new Thintanium collection has been well received within the eyewear industry and within the whole design community across the world. Lindberg Thintanium has already achieved huge recognition so far, gaining two of the most sought after design awards: “The Red Dot” Best of the Best” – the highest award in the competition, reserved for the very best products, and the “iF Gold Award” – the best award by iF design where Lindberg and 74 others received the honour out of 10,000 applicants. The feedback we received is that the Lindberg Thintanium collection is the distinguishable benchmark for the future of titanium eyewear.